From microbrew to microfiber: The science of fermentation in fashion

On a Paris runway, an ethereal gown by Iris van Herpen shimmered under the lights — but silkworms didn't spin its threads. They were produced by microbes, painstakingly engineered by Spiber to make an optimized version of silk protein, grown in giant fermentation tanks.

Across the world, Hermès has reimagined its classic Victoria bag using mycelium leather from MycoWorks. Stella McCartney also debuted handbags made with Bolt Threads’ mushroom-based Mylo™—a pioneer in mycelium materials before the company, now Bolt Projects Holdings, pivoted fully away from textiles into cosmetics. These aren't science stunts— they're commercially viable, runway-ready products showing that biotechnology can deliver fabrics as luxurious as nature's finest, with properties fine-tuned in the lab.

Fermentation, historically applied in food, pharmaceuticals, and industrial chemistry, is now emerging as a transformative tool in material science for fashion. Through the genetic manipulation of metabolic pathways of microorganisms such as bacteria, yeast, and fungi, researchers are engineering products with reduced environmental impact and entirely new performance profiles. These biofabricated materials are entering both luxury and commercial markets, signaling a shift away from extractive models of production.

Fermentation, an old and new technology

Fermentation, in its broadest sense, means using microbes, such as yeast or bacteria, to fundamentally change molecules. Humans have harnessed it for millennia. The form you’re probably most familiar with is winemaking, an example of submerged ethanolic fermentation, where yeast converts grape sugars into ethanol and carbon dioxide while producing hundreds of secondary molecules that shape aroma and flavor.

In coffee production, the beans are submerged in water so microbes can break down the sticky outer layer. As they metabolize these sugars, they generate flavor-active molecules that influence the final cup’s taste profile.

There are lots of other fermented foods in your kitchen, including recent developments — some alternative meats, such as Quorn™ and Meati, go through fermentation before reaching your dinner table.

In modern fermentation, many aspects are controlled, in sharp contrast to traditional fermentation, where outcomes often depend on ambient microbes, seasonal conditions, and less precise handling.

Today, scientists can use specific organisms (rather than relying on those present in the surroundings) and prevent contamination by unwanted microbes. Fermentations are typically done in closed, controlled vessels known as fermenters or bioreactors, which allow precise management of environmental conditions. That way, everything from temperature to pH can be measured and adjusted to get the best possible result. This level of control enables an efficient, reproducible, and scalable process, opening the door to fermentation beyond food—into textiles, dyes, and other biomaterials—where the same precision can deliver entirely new classes of products.

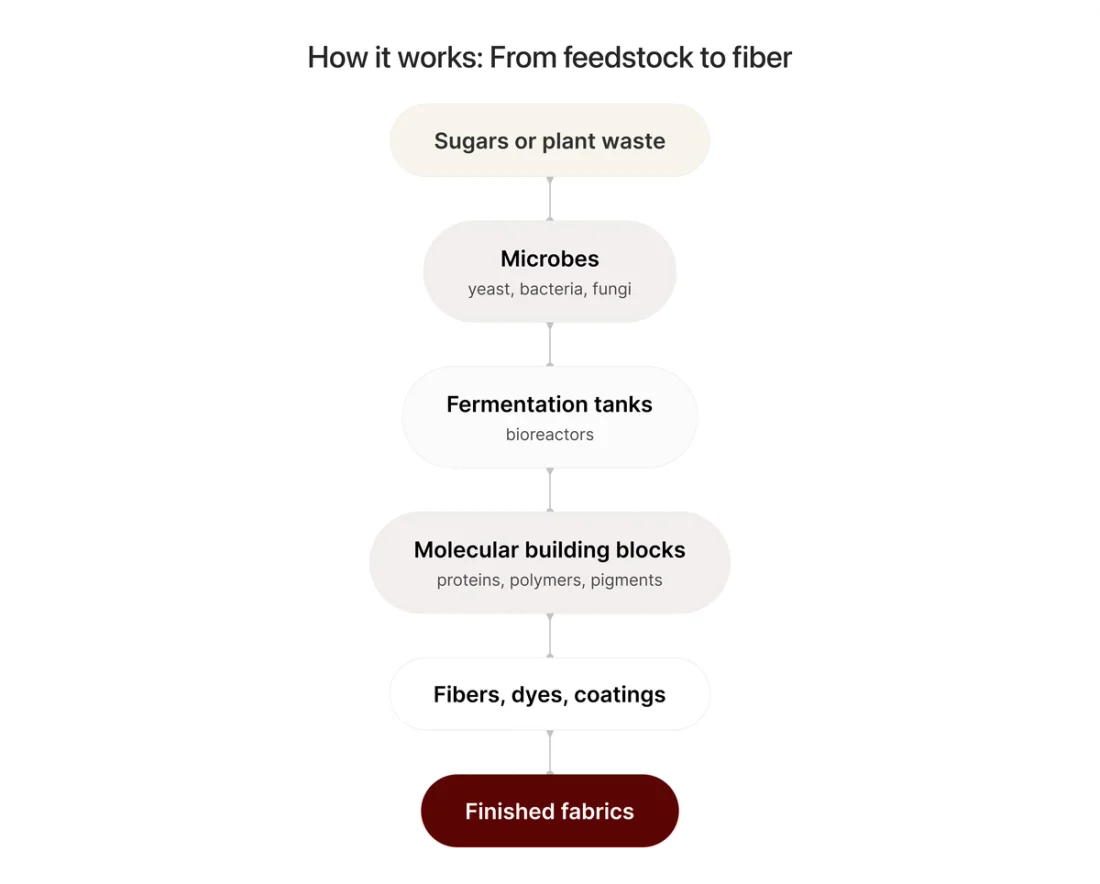

What’s actually happening? Microbes feed on sugars inside a bioreactor, producing proteins and pigments that form the basis of new fibers and dyes.

Ancient roots: The first microbial textiles

Microorganisms have historically played a critical yet often unrecognized role in textile processing. Long before we had synthetic chemistry, fermentation let early artisans extract, soften, dye, and preserve natural fibers. These methods, developed through centuries of practice, are the first step in a long relationship between microbiology and materials technology.

Retting, a submerged fermentation, is among the earliest documented uses of microbial activity in fiber processing. In this technique, bast plants such as flax and hemp are left to soak or dew-rot under ambient conditions, allowing enzymes produced by bacteria and fungi to degrade the binding between the fiber and the stem. This microbial breakdown makes mechanical separation easier and improves spinnability.

Anthropological evidence suggests that these microbial practices were developed through iterative experimentation and handing down oral knowledge. Although the underlying biology was not understood, the effectiveness of fermentation was well established across cultures. From those early and simple fermentation technologies, the advances in fermentation technology combined with synthetic biology are transforming the textile industry.

Designer microbes, grown to order

In today's textile manufacturing, fermentation has gone from cottage craft to precision science. Researchers are using synthetic biology to reprogram microbes to produce raw materials. Instead of mining petroleum or growing livestock, microbes are fed sugar or waste and coaxed into making everything from fibers to dyes. These bioengineered strains are often hosted in bioreactors, their conditions carefully monitored and controlled for optimal yield, purity, and productivity.

Bio-leather

Take bacterial cellulose, for instance. These cellulose fibers, secreted by acetic acid bacteria, form gelatinous mats that can be harvested, shaped, and dried into leather-like materials. Modern Synthesis, a UK startup, uses this technique to craft textiles that are both breathable and biodegradable. They combine the microbial mats with hemp to create structured forms, such as the Bou Bag, which debuted in 2023 in partnership with the fashion brand GANNI. Their approach combines ancient fermentation with machine learning, allowing them to optimize microbial growth patterns for shape, structure, and strength.

Microbial textiles can be grown to fit design, not the other way around.

Bio-silk

Silk, too, is getting a microbial makeover. Rather than farming silkworms, companies like Spiber have engineered microbes to produce silk proteins by inserting genes from spiders or silkworms. After fermentation, the proteins are spun into fibers that are as soft and strong as the originals. Spiber's Brewed Protein™—a fermented version of natural silk proteins, designed for apparel and engineered to maintain its dimensions even when wet—is produced at its plant in Thailand. It has been featured in jackets by The North Face Japan and haute couture pieces by Iris van Herpen. Brewed Protein shows how fermentation can produce not only nature-identical materials, but also improved versions with properties tailored beyond what nature provides.

Bioplastic - PLA

One of the earliest examples of fermented, bio-based material is Ingeo™, a PLA-based fiber developed by NatureWorks—a joint venture between Cargill and Dow Chemical, and introduced commercially in 2003. Made from sugars that are fermented into a renewable polymer called polylactic acid (PLA), Ingeo was among the first commercially successful synthetic fibers made entirely from renewable resources. It has found applications in apparel, nonwovens, carpeting, and performance wear, demonstrating early on that bioplastics can meet diverse textile requirements while reducing reliance on fossil fuels.

Bioplastic - PHA

Building on these early successes, Mango Materials offers a striking example of advancing a material with a more extended history. Polyhydroxyalkanoates (PHAs) are a bio plastic first discovered in the early 20th century. Traditionally, production relied on sugar or plant oils as feedstocks. Mango Materials is making them more commercially viable and more sustainable by fermenting methane—a potent greenhouse gas—to create biodegradable PHA polymers. These can be processed into fibers, films, and coatings for textiles, as well as molded into buttons or accessories, all of which naturally decompose at the end of their life.

This approach not only revisits an established biopolymer for modern textile applications but also illustrates how industrial emissions can be repurposed into clothing and components that return safely to the environment. This progression from innovative fibers to environmentally conscious processes sets the stage for the next frontier in fermentation: rethinking how we add color to textiles.

Microbial dyes: Color without chemicals

Textile dyeing is a principal environmental offender, accounting for roughly 20% of industrial water pollution. But fermentation is offering a way to color fabrics without the toxic fallout.

At Colorifix, scientists start by identifying genes that produce natural pigments—whether from plants, animals, or microbes. These genes are inserted into microbes that are grown in fermenters. After fermentation, the microbes are applied directly to fabric, where they produce and fix the pigment in one step. This method slashes water use by 77%, cuts out toxic mordants, and reduces energy demands. Their dyes have already been used in collections from Pangaia, Vollebak, and H&M. More importantly, Colorifix has proven that biotech dyes can be compatible with existing industrial dyeing equipment—lowering the barrier to widespread adoption.

In California, Huue is focused on denim's iconic blue: indigo. Their engineered microbes produce indigo precursors without the hazardous chemicals typically used in dye baths. What results is a safer, cleaner route to the same classic color. Other companies are focused on other colors. Living Ink, for example, is developing black pigment derived from algae instead of petroleum, offering a carbon-negative alternative to carbon black.

Environmental payoff

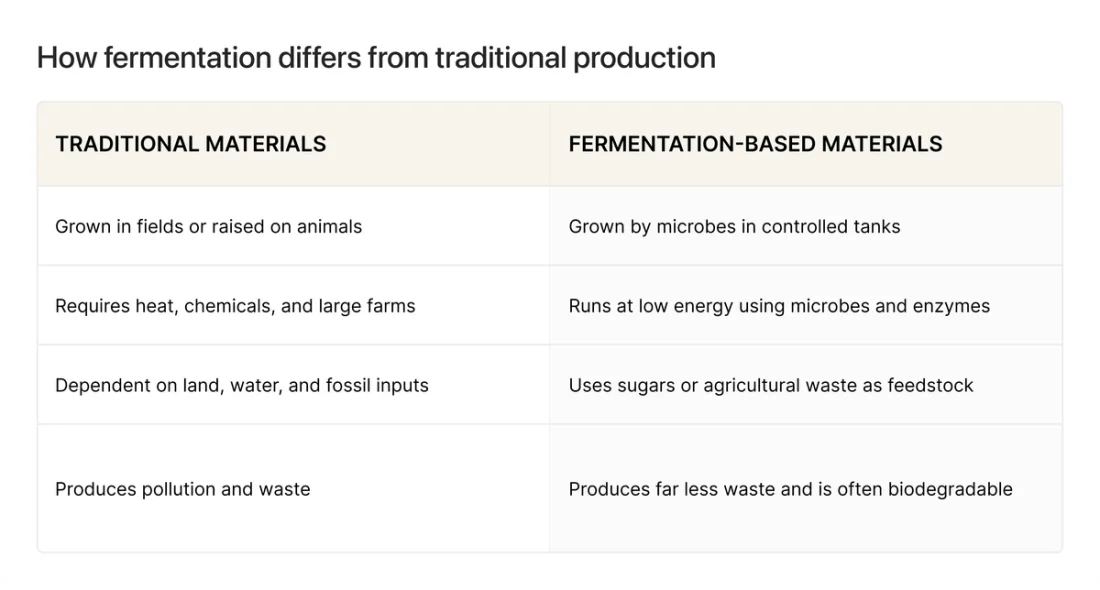

The traditional supply chain was based on an unsustainable model of resource extraction and on processes that pollute air, water, and soil. Fermentation flips that script.

Water usage drops dramatically—by 50 to 90 percent in some cases. Carbon footprints shrink when textiles and colors are made by microbes fed sugars or even methane instead of using fossil fuels to make them. Toxic chemicals can become unnecessary, and many of the new materials—like mycelium leather or PHA-based fibers—are compostable.

Performance doesn't need to be sacrificed either. Mycelium leather is supple and strong, able to withstand wear while remaining lightweight. Brewed silk offers the same breathability and elasticity that made traditional silk so desirable, and bio-nylons match the stretch and resilience of their fossil-based counterparts. As materials improve, brands and manufacturers are also learning how to use them effectively—understanding their behavior in different garments, adapting production techniques, and creating new aesthetic possibilities unique to biofabricated textiles. At the same time, life cycle analyses are beginning to quantify the environmental benefits in rigorous terms, helping brands make smarter, science-based material choices.

These innovations also allow for a more decentralized model of production. In theory, fermentation-based materials can be grown anywhere with the proper infrastructure, reducing reliance on long supply chains. Localized biofabrication hubs could slash shipping emissions, create regional jobs, and bring textile production closer to urban centers.

And importantly, these new materials also open doors to circularity. Garments made from microbial fibers can often be composted at the end of life, or enzymatically broken down into feedstock for new fermentation cycles—closing the loop in a way traditional textiles cannot.

The road ahead

Despite its potential, the fermentation-driven transformation of the fashion industry faces significant technical and structural challenges. Biomanufacturing facilities capable of producing microbial materials at a commercial scale remain costly and limited in number. Current production yields for many fermentation-based materials can’t compete with conventional fibers like polyester or cotton on either cost or volume.

Another critical barrier is infrastructure. From production to supply chain, the systems and processes within the fashion industry would need to be overhauled to adapt to biomaterials. With most production moving away from North America and Europe, these sites are often far away from the centers of biotech innovation.

Consumer perception also remains a hurdle. Although there is growing demand for sustainable alternatives, misconceptions about genetic modification, safety, or cleanliness could slow adoption if not addressed proactively. Broad consumer education, clear labeling, and transparent environmental data will be necessary to build trust and encourage widespread use of these novel textiles. Furthermore, robust regulatory frameworks for evaluating the safety, environmental impact, and labeling of biofabricated textiles are still under development in most jurisdictions.

Despite these challenges, momentum is growing. Leading fashion brands are investing in R&D partnerships and pilot-scale trials. Several academic and technical institutions have introduced biofabrication modules into textile and fashion curricula. Life cycle assessments are increasingly demonstrating the environmental benefits of microbial materials, and early commercial products are validating their performance in real-world conditions.

From ancient craft to a sustainable future

Fermentation once gave us bread, beer, and the first softened plant fibers. Today, it offers designers a palette of materials not limited by nature—fabrics that are nature-identical when desired, or reimagined with enhanced strength, resilience, or sustainability. With microbes as programmable factories, the industry can rethink how textiles are created, dyed, used, and recovered. Once scaled, this shift could mark a new era in fashion: one where the most desirable fabrics are not just inspired by nature, but improved on by science and in harmony with the environment.

More articles

The collaboration at the heart of BioFur: “The right partners drive success”

BioFur founder Kym Canter and science partner Gerard Nijhoving discuss the powerful collaborations that drive the company’s successes.

4 collaborations where biology met design in 2025

From fermented fibers to seaweed-based buttons.

Alternative silk explained

Silk is evolving from cocoons to lab-grown fibers

Become an insider

Stay in the loop on the latest updates.