The collaboration at the heart of BioFur: “The right partners drive success”

“We’re the second generation of founders in the biomaterials space and we’re learning from the people who came before us.”

- Kym Canter

In 2020, Gerard Nijhoving heard Kym Canter talk about her desire for a high quality bio-based fur, and thought “we can do that.”

Along with Chinese mill Nice Gain and Concept III Textile, these are the people behind BioFur’s initial line — BioBunny, BioSherpa, and BioWool. At annual functional fabric fair Performance Days in 2025, the sherpa was picked as one of the top 10 industry innovations.

Animal, mineral, vegetable: refusing to compromise on quality and impact

The story of BioFur goes back further, to a moment when Kym couldn’t justify her competing views on animal wellbeing and wearing fur.

As a fashion editor, stylist, and eventual consultant for fur brand J. Mendel, Kym had quite the collection of fur coats.

“I thought fur was luxury, I thought I could love animals and still work there. It took me a long time to wrap my head around the fact that that was a really hypocritical stance,” she says. “One night I was getting ready to go to a party and I put on one of my most fabulous furs and I looked in the mirror and I said there's no way you're going to a party dressed like this.”

Disappointed with the faux fur options available, she decided to make her own. This led to the establishment of House of Fluff, which quickly became a celebrity favorite.

However, switching from an animal product to a petroleum product didn’t seem like a true success story for Kym.

“Why am I switching from dead animals to something that’s still screwing with the earth? This is not a win. So I immediately started an innovation pillar — that was 2017,” Kym says. “I talked to everyone I could find and I got a sense of who I needed. I knew I was looking for a polymer or material scientist working in this space.”

That’s when she got a LinkedIn connection request from Gerard, who had just seen her speak at the 2020 Textile Exchange Conference.

From faux grass to faux fur

Gerard Nijhoving was born and raised in Emmen, in the Netherlands. It’s an industrial town, with strong connections to the plastic and fiber industries, and Gerard studied plastics engineering and business management.

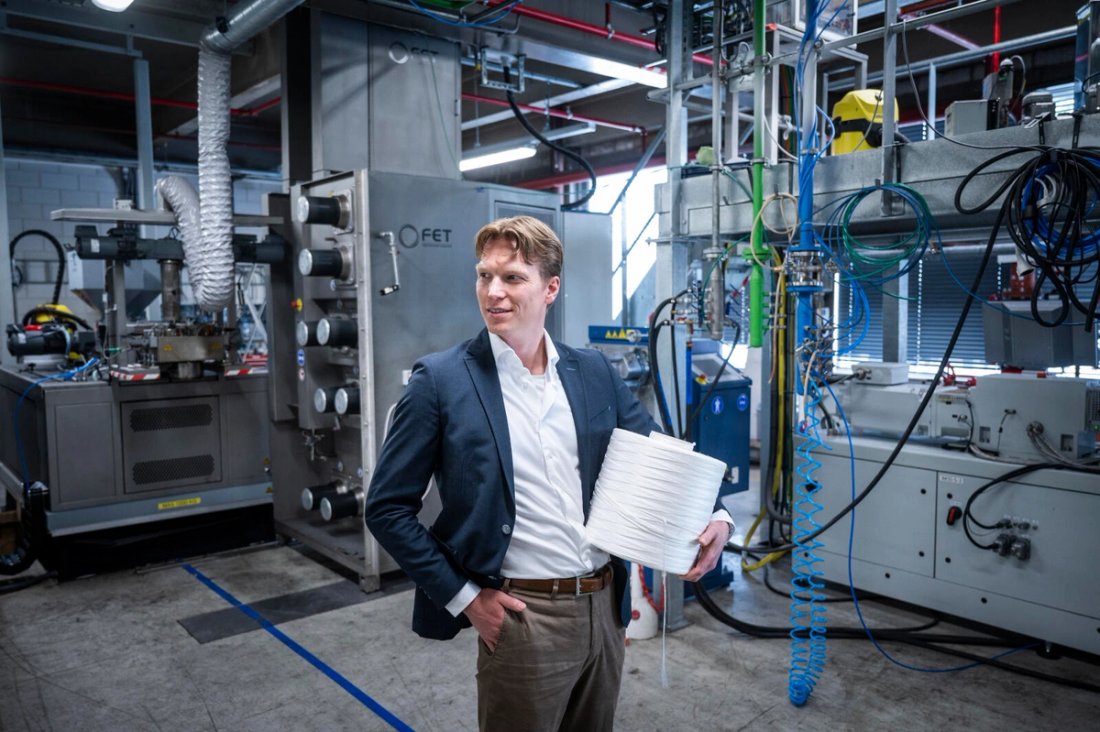

After almost a decade of working and consulting in the field, in 2015 he acquired Senbis Polymer Innovations — based right back in his home town.

“We are investing in biodegradable and bio-based plastics for different applications. It can be challenging to achieve the right mechanical performance, but that’s what we’re good at. We come up with innovative solutions,” Gerard says.

The most common bioplastic is PLA, which is a fermented biopolymer. PLA isn’t suitable to replace many technical or high performance plastics and one of Senbis’s big projects has been working on a biopolyester that would have a wide range of applications.

When he heard Kym’s call out for a bio-based faux fur, Gerard was pretty sure she didn’t need a whole new polymer, but for someone to figure out how to effectively process existing ones.

A glance at the Senbis website gave her confidence.

“I looked up his company and they had made fake grass. And I thought, well, if they're making astroturf and grass, which is kind of spiky, maybe they're going to be able to make fur.”

In addition to creating a quality faux fur, Kym had four non-negotiables when it came to the final product:

- It had to be animal free.

- It had to be completely free of petroleum.

- It had to be made on existing machines.

- It had to have price parity.

“We decided that on the road to doing noble furs like foxes and minks, we started out with shearling and bunny because it was a little easier to achieve and it's a huge segment of the market,” Kym says.

The power of partnership

“We had a lot of iterations in the development between the Chinese mill and our final process here in the Netherlands,” Gerard says. “I think what’s often lacking is innovation in the supply chain. We had this cooperation and collaboration with Nice Gain, the mill, where they told us what they had already tried and we were able to modify and adapt from there.”

The new product requires tweaks to the existing process, but it works on existing equipment with different settings or processing times. “In the end we got to a very good fur. I’m not one to judge, but Kym knows. We kept on going until she was happy.”

After a few years of development, BioFur has a product that meets all Kym’s requirements. It feels good, is certified biodegradable, works in the current mills, and has price parity with existing plastic-based counterparts. The new product can be adapted to a brand’s requirements for color, length, and even curliness.

“I think the biggest thing is that there’s inherent qualities in the textiles and we have to be able to match on price and hand feel,” Kym says. “There’s no coating, there’s no backing that comes from another material. It's 100% bio-based, USDA certified, compost certified. And it’s super soft.”

You gotta have trust

Both Kym and Gerard emphasized the importance of trust and partnership in creating BioFur’s initial line.

“A collaboration between all parties is pretty unique, especially in the innovation space at the time, when people were raising huge amounts of money,” Kym notes. “The genius of our collaboration is that everybody came with a different expertise. No one could have done it alone and everyone’s expertise is in a very defined area.

“Plus they all turned out to be nice people — that’s an unpredictable thing in and of itself.”

There are contracts between all the involved people and companies, but with four organizations in three countries, trust is necessary.

“It's very rare in this world, I think, to work like this. There is a lot of trust between each other,” Gerard says. “We invested up front, then the mill took their work, now Kym and Concept 3 are working with brands. Everyone is contributing at their stage. We all add value for each other, and then magic happens.”

The future of fur: From royal gifts to big brands

In 2023, ahead of a visit from the King of the Netherlands, Senbis made two prototype BioFur scarves in Dutch orange. While he couldn’t give them to the reigning couple at that time, Gerard recently gifted these scarves to Prince Constantijn of the Netherlands, who is very involved with local tech investment and innovation.

The scarves were the first BioFur prototypes — very expensive scarves, Gerard jokes — but now the company is ready to sell at scale.

“We’re now actively out talking to brands and looking for brand partners that want to use the fur. We're completely able to scale and can make as much as anybody wants us to make,” Kym says. “It's been a long road and it's real persistence when you look at the timeline. Now I'm excited to be able to go to market with as many brand partners as possible.”

They’re in talks with a range of brands, from luxury to children’s toys, working to slowly replace animal and petroleum products with biodegradable, compostable faux fur.

Kym hopes the next generation of biofashion innovators learn from their process.

“This can work without raising tons of money — good old-fashioned grassroots partnership can get you somewhere. It’s the right partners at every stage that drives success.”

More articles

4 collaborations where biology met design in 2025

From fermented fibers to seaweed-based buttons.

From microbrew to microfiber: The science of fermentation in fashion

How fermentation produces fibers, dyes, and materials

Alternative silk explained

Silk is evolving from cocoons to lab-grown fibers

Become an insider

Stay in the loop on the latest updates.